Coriolis mass flow meters are used to measure mass using inertia. A gas or a liquid flows through a tube that is being pulsated by a tiny actuator. This pulsation results in a phase shift due to adding some Coriolis acceleration to the fluid stream. This acceleration results in a quantifiable force applied to the tube. The force is directly proportional to the mass, and the meter detects the resultant angular momentum to determine the mass flow. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

Aalborg Instruments & Controls is a globally recognized manufacturer of precision instrumentation for flow measurement and control. We offer variable area flow meters, thermal mass flow controllers, and more. Since our founding in 1972, it has been our commitment to develop, produce and deliver the highest quality products and services, as well as consistently meet or exceed customer...

Ryan Herco Flow Solutions is a leading national distributor for fluid handling products. Our family of products include; Flowmeters, sensors, instrumentation tubing and hose, process pipe and fittings, valves, pumps, filters and filter systems, storage and drums, and corrosion resistant structural products. We have 29 U.S. Service Centers ready to serve you.

Our flow meters are meticulously designed with you in mind. Our products have an unrivaled reputation, because we spend hundreds of engineering hours working on new and better ways to improve our products. No matter what you need, we can get if for you! Our staff is dedicated to helping you every step of the way. Contact us today for more info!

We are ONICON Incorporated, a leading manufacturer of flow meters and energy measurement systems. Our products and solutions are used in a wide range of applications, including HVAC, building automation, and industrial processes.

More Coriolis Flow Meter Manufacturers

Coriolis flow meters can measure flow into the tube going either forward or backward. In most configurations, the tube is vibrated between two locations where it is anchored. It is possible to picture this design rattling a mass and spring combination. This arrangement will vibrate once it is in motion at its resonance frequency, which depends on the mass of the assembly. The minimum driving force required to maintain a steady vibration of the filled tube leads to the selection of this resonance frequency.

Design of a Coriolis Flow Meter

The Coriolis effect, an inertial force brought on by the Earth's rotation, is exploited by this type of flow meter to produce an extremely accurate estimate of mass flow and the fluid density. The most common components of these flow meters are a drive unit, displacement sensors, and a U-shaped flow tube with an inlet and an exit that allows for flow. The flow is initially directed into the flow tube via the intake, where it is then subjected to an oscillatory excitation force that causes the tube to vibrate. Once the vibration has been accomplished, the fluid flow will cause the tube to rotate due to the Coriolis effect. Due to the acceleration solely on a single side of the tube, the inlet, and deceleration on the other, this effect rotates the tube (the outlet). As a result, there is a time delay since the intake may detect the stream before the output can. The gas or fluid mass flow rate is approximately equal to this time delay. Hydrogen gas, bituminous fluids, natural gas, and water are just a few of the fluids and gasses that can have their mass flow rates measured by Coriolis flow meters. Coriolis flow meters are frequently built from corrosion-resistant materials like stainless steel and metal alloys because some of the fluids or gasses they measure are corrosive.

Components of a Coriolis Flow Meter

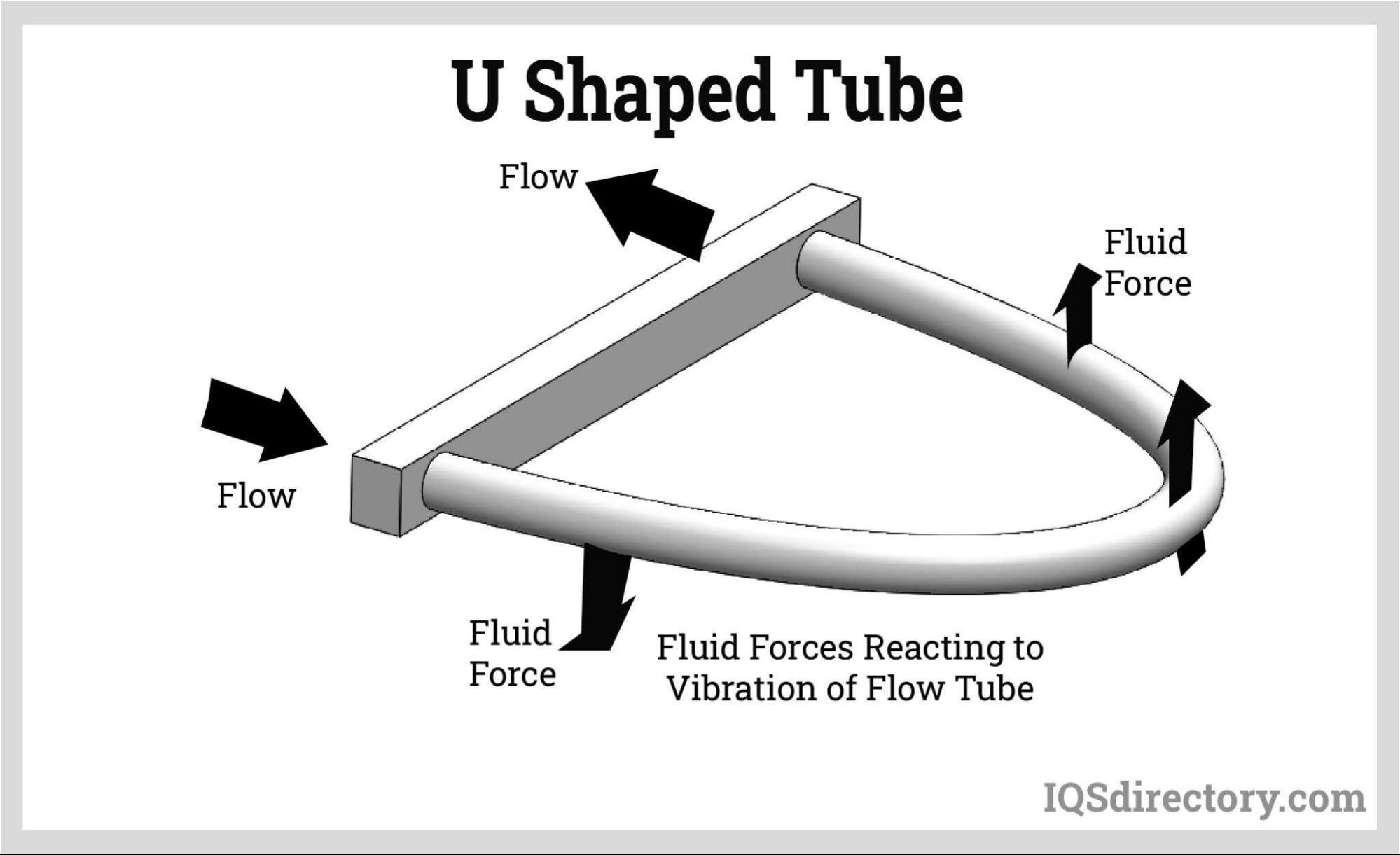

U-Shaped Tube

The U-shaped tube is the most crucial component of a Coriolis flow meter because it is the source of the readings. Materials that enter tubes oscillate in an angular oscillatory motion, which causes the tube to deform. The arrows in the diagram below illustrate how a liquid or gas moves through the tube.

Exciter

The exciter makes sure that the tube is constantly oscillating and moving. The oscillation motion is uniform when there isn't any flow. The exciter is situated at the lowest position of the tube between the measuring sensors, as shown in the image below.

Electrically-Dynamic Sensors

At the entrance and outflow, sensors are placed to track oscillation. Even though there is no flow, the oscillation is uniform, but it changes when a fluid or gas is introduced. The entrance and exit parts of the tube oscillate in opposite directions due to the inertia of the liquid. The sensors detect the phase shift, also known as the shift in oscillations in both time and space.

Phase Change Sensors

The phase shift, which is the end consequence of the oscillatory motion of the tube, is a true measure of how much liquid or gas is going through the pipe. A linear result equal to the flow is produced by its measurement. This kind of measurement is usable with any material because it is not dependent on the contents of the tube. These sensors additionally gauge the fluid or gas's inherent frequency. The frequency change—the number of times the tube swings forward and backward in a second—relates directly to the material's density. The volume flow rate is calculated by measuring the rate of mass flow and density. Finally, temperature is measured as one of the different measurements to account for dynamic changes brought on by the contraction and expansion of the tube.

Control Panel

A Coriolis flow meter uses the data collected from tube oscillations and phase shifts to calculate liquid or gas volume, mass, and density. Depending on the kind of meter, the display on its front can be adjusted to show mass flow readings in pounds or kilograms. Coriolis flow meters are quite adjustable. They might be very small, like 0.04 inches (1 millimeter), or very large, to accommodate petroleum and oil operations. Before buying and installing the meter, it is necessary to decide on several criteria that affect the choice of a flow meter.

Choosing the Proper Coriolis Flow Meter Supplier

To ensure the most positive outcome when purchasing Coriolis flow meters from a Coriolis flow meter supplier, it is important to compare several companies using our directory of Coriolis flow meter suppliers. Each Coriolis flow meter supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each Coriolis flow meter business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple Coriolis flow meter companies with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services