Hydraulics is a method of using high pressure fluids to produce mechanical energy. It is a liquid method that uses the principles of pneumatics with fluids instead of air. The concept of hydraulics is based on fluid mechanics, which focuses on the properties and characteristics of fluids. Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

At Wyatt Engineering LLC, we specialize in delivering precision flow measurement solutions tailored to meet diverse industrial needs. Our expertise lies in designing and manufacturing flow meters that offer reliability, accuracy, and durability for a variety of applications. Through our advanced engineering capabilities, we create flow measurement devices that seamlessly integrate into systems...

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

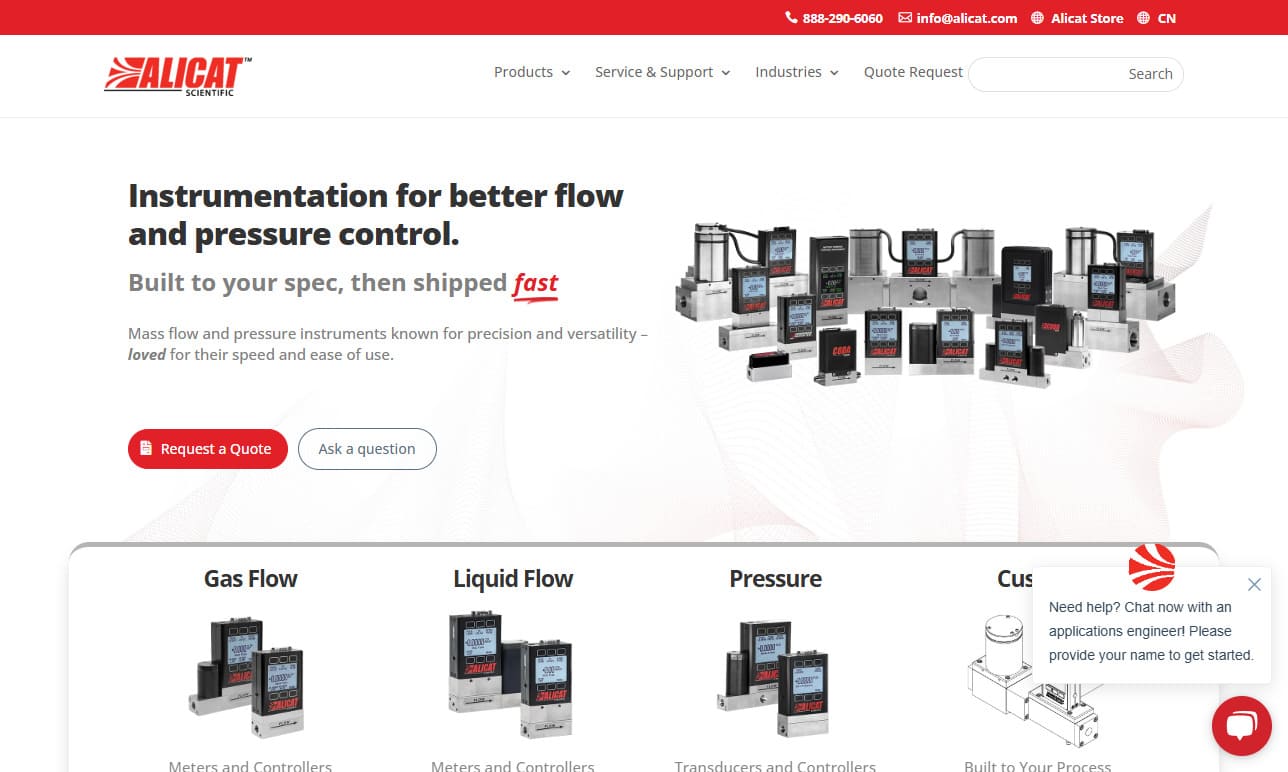

At Alicat Scientific, Inc., we are dedicated to designing and manufacturing high-performance flow meters that meet the most precise and demanding requirements. Our expertise in fluid dynamics allows us to develop solutions that span a wide range of applications, including laboratory research, industrial automation, environmental monitoring, and aerospace.

At Orange Research Incorporated, we are dedicated to providing industry-leading flow measurement solutions that excel in both accuracy and reliability. Our line of flow meters is designed to serve diverse applications, meeting the unique requirements of industries that depend on precise fluid monitoring, from chemical processing to energy production.

More Hydraulic Flow Meter Manufacturers

What is a Hydraulic Flow Meter?

A flow meter is a method of measuring the volume of a liquid as it passes a fixed point on a pipe or tube. Measurements are taken in liters per minute or gallons per minute. They measure linear, nonlinear, mass, or volume of a liquid’s flow rate. The key factors that hydraulic engineers watch are flow and pressure to get an accurate and precise measurement of a system. The main function of a hydraulic flow meter is to determine the efficiency and accuracy of the systems operation and performance.

The term hydraulic flow meter is a generic method for describing a hydraulic flow measuring device. Since hydraulic fluids come in different viscosities and with different flow rates, hydraulic flow meters are adjusted and produced to fit the conditions of the type of fluid they are measuring.

How a Hydraulic Flow Meter Works

Hydraulic flow meters are known as gauges, indicators, and liquid meters depending on where they are being used and the industry. They are normally made from resilient material with the ability to withstand the stress and pressure associated with liquid pressure. The common types of metals utilized are brass, aluminum, or stainless steel. Aluminum flow meters are used for measuring the flow of noncorrosive water based or petroleum based fluids with pressures of up to 3500 psi.

A hydraulic flow meter can be positioned in any part of a hydraulic line to identify the flow rate. Since not every hydraulic system is the same, there are flow meters with varying port sizes to fit different systems. The meter itself has three main parts, which are the device, a transducer, and transmitter.

The transducer on a hydraulic flow meter measures the velocity of the liquid. They can calculate the flow level or the amount of flow. The transducer senses the passage of the flow through the measuring device and sends a signal to the transmitter. The volume of the flow is proportional to the cross sectional area and the fluid velocity with the mass flow being proportional to the density and volume of the fluid. The data from the calculations appears on the hydraulic flow meter gauge.

Types of Hydraulic Flow Meters

Though a hydraulic flow meter may be a necessity for an operation, it is important to be careful in selecting the proper flow meter for the job. The main concern when choosing a flow meter is the consistency, viscosity, and characteristics of the fluid to be measured, which include lubrication in the fluid, compressibility, demulsibility, combustibility, and heat dissipation in the fluid.

Three of the basic types of flow meters are variable orifice, gear type, and turbine type. Each of these is designed to measure the flow of different types of hydraulic fluid and each provide readouts in a different form. When choosing a flow meter, engineers initially determine how they want the data presented and how it can be used as a measure of the efficiency of the system.

A variable orifice flow meter is a head flow measuring method. It contains a piston or ring where pressure is applied as the result of fluid flow. As the movement in the liquid increases, the piston moves and increases the opening in the line. The provided readout is analogue, which comes from a link to the piston or ring.

The gear type of flow meter uses positive displacement and has a pair of gears around which the fluid in the line passes. The transducer is connected to one of the gears and generates a pulse as the second gear passes under it. Like a windmill, the rotation of the gears is created by the fluid flow.

Turbine flow meters have a turbine rotor and blades. The rotor is connected to the shaft and placed between two flow straighteners. The force of the fluid rotates the turbine, which has a transducer connected to it to provide a flow reading. Turbine flow meters can be used with both fluids and gases.

Benefits of a Hydraulic Flow Meter

Hydraulic flow meters serve several functions above and beyond their use as a measuring tool. When hydraulic equipment is in constant use, these specially calibrated devices supply data that can prevent accidents, assist in maintaining equipment, and provide valuable data regarding equipment operation.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services